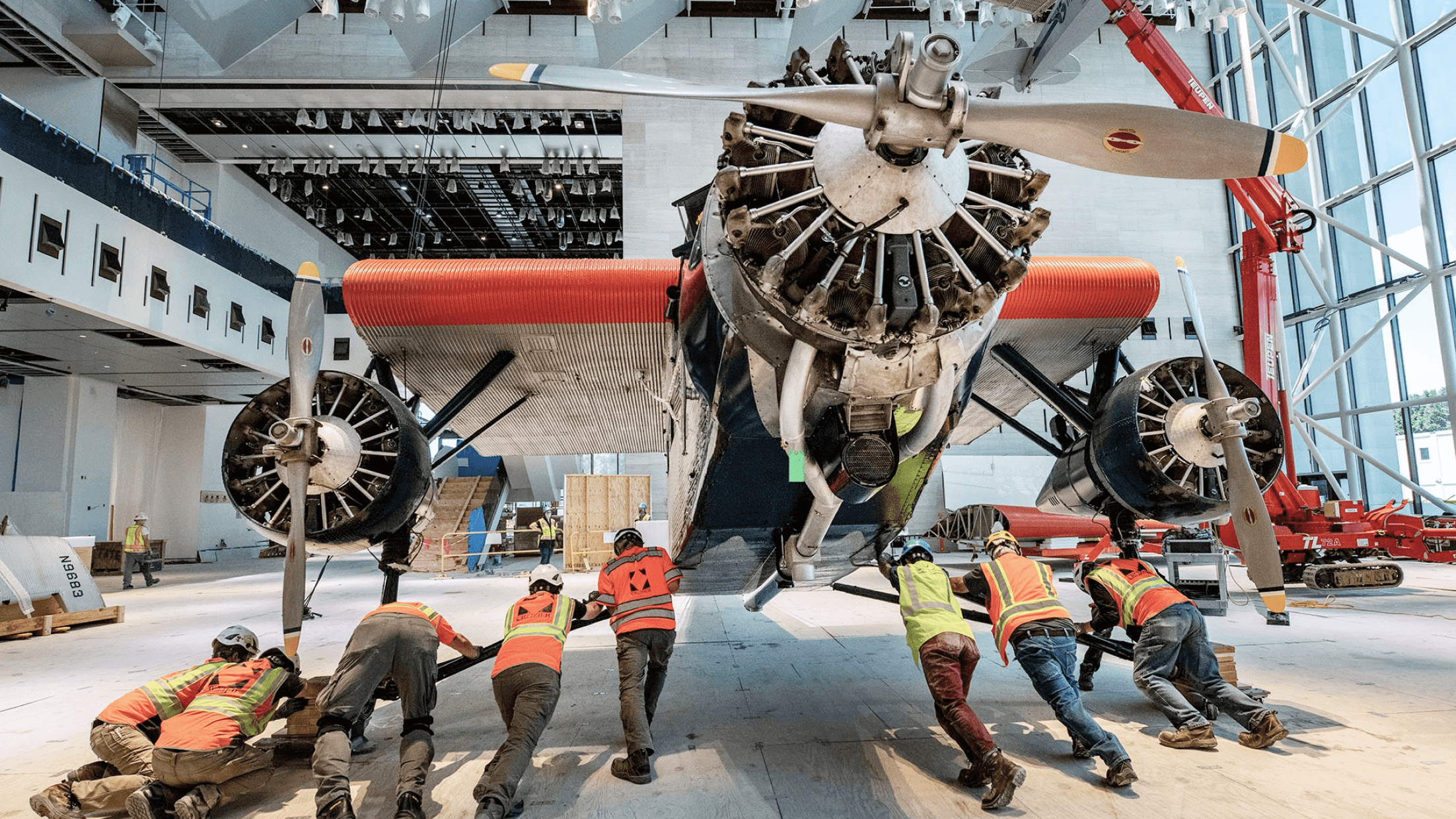

Crozier team members navigate the "Tin Goose," a 1928 Ford 5-AT Tri-Motor into place in the "America by Air" gallery. Photo courtesy of Jim Preston / The Washingtonian

"With artifacts literally the size of jet planes, renovation is no small feat," wrote the Washingtonian about the Smithsonian National Air and Space Museum's seven year plan to redesign all of its galleries, including 23 exhibits. To tackle this massive project, Crozier had to first submit a 600+ page Artifact Move Logistics Feasibility Study including a Statement of Work (SOW) and a budgetary estimate to Congress. Once approved, our engineers got to work deinstalling the museum. This process involved rigging, disassembling, inventorying, condition reporting, barcoding, packing, and transporting more than 2,700 artifacts in total. Once disassembled, the number of items grew.

After the deinstall, Crozier was awarded the contract to reinstall and suspend the large artifacts in the western portion of the museum. Engineers had to consider the weight of each plane and the potential weight of snow on the building's roof to figure out how to safely hang them. By the time the job was done, the landmark location was practically a brand new museum.

Stay in touch and up to date about industry news, events, trends, and much more.